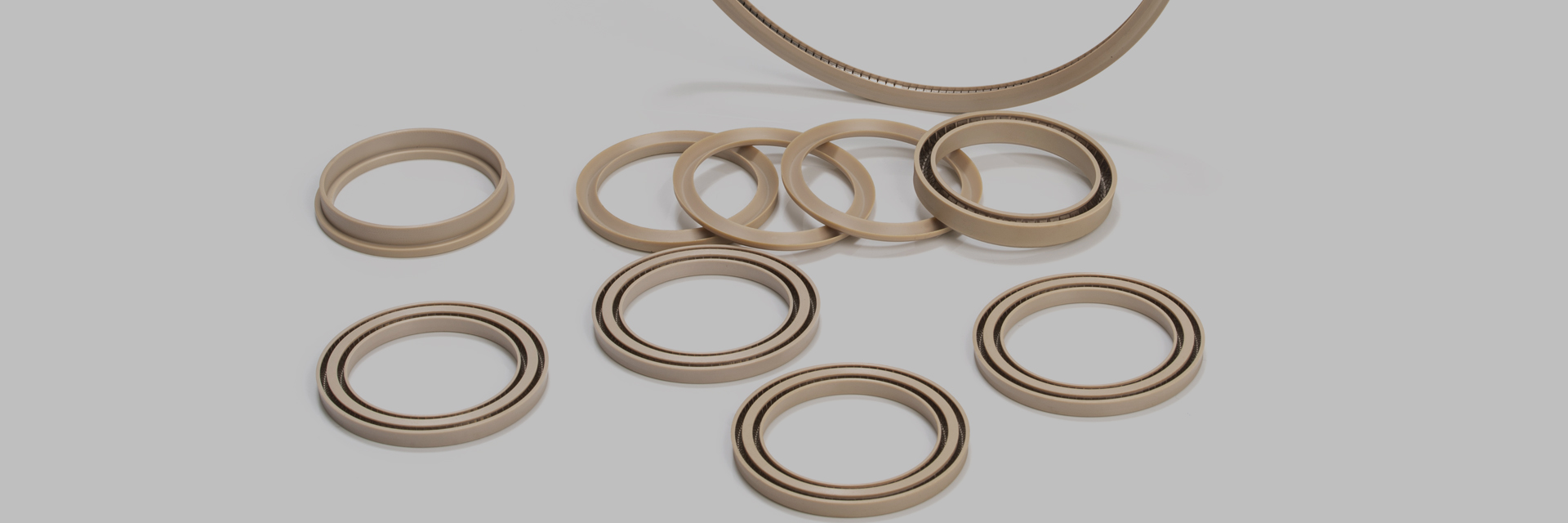

动密封件

返回材料PTFE活塞环主要在滑动过程中(特别是在有侧向力的情况下)防止活塞和气缸缸体之间的金属接触,其装配简单且耐磨。由于其具有良好的耐介质性,活塞环可用于多种介质条件,从矿物油基液压液、环保液压液和水油乳液到阻燃液压液和其他干运行应用。活塞环能提供非常好的滑动性能、良好的紧急运行性能以及高耐磨性。此外,可以有助于降低机械振动。

主要优点

出色的干摩擦性能

拥有不同的开口形式以适用于各种工况压力

与金属和塑料结合使用时的摩擦系数极低

耐几乎所有固体、液体和气体化学物质

开口形式安装方便

典型应用

旋转气泵

液化石油气泵或真空泵

旋转式压缩机

无油静音空压泵

材料选择

| 材料 | 特性 |

| 纯PTFE | Piston rings are used in cases that require very high chemical resistance and generally in low velocity and low pressure applications. But Virgin PTFE is too soft and has a very high coefficient of thermal expansion. |

| PTFE + 碳 | Piston rings are most commonly used. They have very high resistance to wear and deformation under load and perfect wear resistance in dry and wet environments. They do not wear off the surface in contact even at high velocities. They have very high heat conductivity. Compared to types with other fillers, their resistance to alkalies is better, but their resistance to oxidizers is less than glass-filled. |

| PTFE + 玻璃纤维 | Piston rings are recommended where chemical resistance is important. Their resistance is low only against alkalies. They can wear off surface in contact at high PV values if surface in contact is not hard enough. Compared to virgin PTFE piston rings, they have higher wear resistance and deformation resistance under load. |

| PTFE + 聚酰亚胺 | Excellent in dry service with low wear rate in vacuum and inert gases. Very low abrasion to dynamic mating surfaces. It's suitable for high speed rotating applications. But the price are most expensive. |

| PTFE + 铜粉 | Piston rings have highest heat conductivity, but their chemical resistance is not good. Generally speaking chemical environments that affect bronze have an effect also on bronze-filled PTFE. Their resistance to deformation and wear under load is good. They can be used at low and high PV values where chemical resistance is not necessary. If surface in contact is not too hard, they are also appropriate at high speeds in dry conditions |

©2025 嘉兴天翊新材料技术有限公司 版权所有 浙ICP备2024101659号